WILSEN V2.3—the Next Generation of LoRaWAN-Based Ultrasonic Sensors

The next generation of LoRaWAN-based sensors from Pepperl+Fuchs offers even more user-friendliness and parameterization options.

In a continuing success story, Pepperl+Fuchs is now presenting the next generation of the well-known LoRaWAN-based "WILSEN" ultrasonic sensors. The battery-operated wireless sensors, which are frequently used in the waste disposal industry, flood protection, and industrial environments, have been given a number of sophisticated customizations and additions. These noticeably increase user convenience and at the same time enable even more precise adjustment to specific application requirements.

Specialists in Level Detection and Distance/Level Measurement

As part of the new generation's introduction, the portfolio of WILSEN devices is being restructured. While devices for common level measurements continue to be marketed under the name "WILSEN.sonic.level," dedicated specialist devices for distance and level measurements are now joining the "WILSEN.sonic.distance" type. Instead of a percentage fill level, these ultrasonic sensors transmit the amplitude value corresponding to the received echo. This provides information on how well the sensor is oriented to the object being detected, for example, and can also serve as an indicator for reliable detection of the object under current ambient conditions.

Ready for Large Tanks and High Bridges with a Special 7 Meter Design

Thanks to an improved distance value resolution of 1 mm, both WILSEN.sonic.level and WILSEN.sonic.distance sensors provide the level of precision required for challenging applications. In addition to the 2.5 and 4 meter versions, versions with a detection range of up to 7 meters are now available to users. This increased detection range broadens the range of applications for the LoRa wireless ultrasonic sensors and allows the detection of fill levels in larger silos and tanks or the level measurement from higher bridges, for example.

Downlink Channel Offers Maximum User Convenience

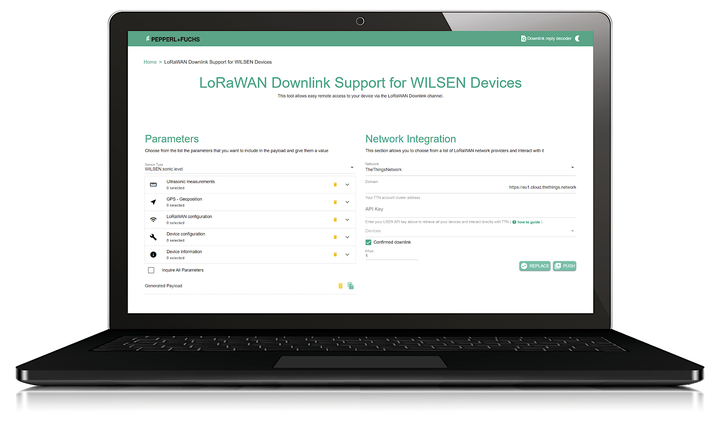

With this new generation, LoRa communication via a downlink channel is also gaining traction with the WILSEN sensors: Once the devices are integrated into a LoRaWAN network, parameter settings in the sensor can be accessed remotely and easily queried or changed. Pepperl+Fuchs also provides a specially programmed web service for this purpose. With just a few clicks, downlink payloads can be created as HEX codes and transferred directly via the Network API Key to message queues in the TTN (The Things Network) and ChirpStack (v3 and v4) IoT platforms.

If an IoT platform other than TTN or ChirpStack is used or no Network API Key is available, the HEX code can also be easily copied and pasted into comparable applications and sent there via downlink. A downlink reply decoder, which is also integrated into the Pepperl+Fuchs web service, allows confirmation messages from the WILSEN sensors to be decrypted into human-readable plain text.

Shortened Measurement and Transmission Intervals

Furthermore, the downlink channel now allows the measurement and transmission interval of the WILSEN sensors to be adjusted to ten minutes without violating the LoRaWAN air-time restrictions. This has advantages, especially in level measurement applications: In the event of predicted rainfall, the WILSEN is switched to the ten-minute measurement interval via downlink beforehand so that rapid level changes and possible flooding risks can be viewed immediately in the measurement data. After the rainfall, the sensor returns to its initial output status—again via a downlink command—to preserve battery life while performing its task.

Calculating Battery Runtimes of LoRaWAN Sensors

To help optimize battery performance even further, Pepperl+Fuchs also offers a free, web-based battery runtime calculator with the new WILSEN generation. This tool allows users to calculate the expected battery life of their WILSEN sensors based on a number of parameters. These include the location (indoor or outdoor areas), measurement and transmission frequencies, and the quality of the LoRaWAN network at the operating location. The results of the calculation help to set meaningful and appropriate sensor parameters for the application and to achieve the longest possible battery runtime. In addition, the tool can be used to estimate battery replacement intervals to avoid equipment failures and costly service work.

Highlights of the Battery-Operated WILSEN.sonic Ultrasonic Sensors

- Industrial-quality wireless IoT sensor for level and distance measurement applications

- Globally standardized LoRaWAN® network for efficient, long-range signal transmission

- Easy to install and operate: downlink channel and mobile app simplify device and system configuration

- Maximum precision due to high resolution and adjustable measurement interval

- Rugged solution, ready for use in harsh environments

- Unmatched ultrasonic expertise: our sensor solutions meet current and future challenges

+44 161 6336431

+44 161 6336431