Optimal Picking and Packing with RFID

Automated process control that works reliably and quickly

The Application

Simple online ordering and the immediate delivery of goods are now commonplace in the B2B and B2C operations. It is taken for granted that precisely the goods ordered reach their destination, even when a wide variety of products is being handled. This goal can only be achieved with sophisticated logistics. All process steps must flow smoothly. One such step is picking, which involves compiling products in a shipping box to be sent on their way. In addition to assigning the correct goods to the delivery, it is also important to pack them optimally. Unused space can create unnecessary additional costs and must be prevented. Ideally, the automatic creation of delivery notes and invoices is linked to the picking process.

The Goal

All of the goods required must be compiled in the appropriate shipping box for each order without errors. The amount of packaging should be minimized wherever possible. Especially in large dispatch warehouses, the processing time per delivery is a key factor and must be kept as short as possible. It must be possible to track and locate the delivery packages using Track&Trace.

The Solution

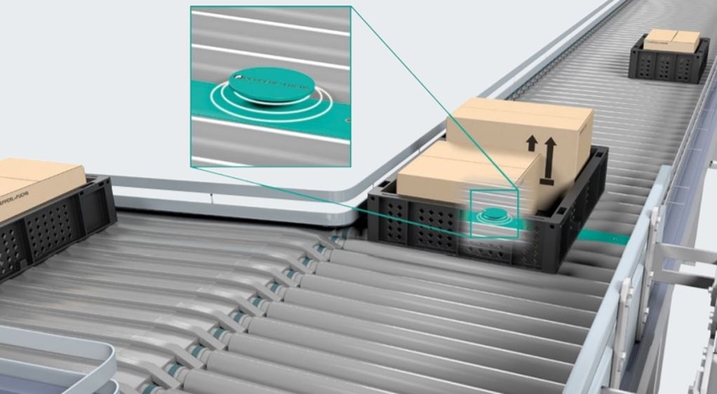

RFID read/ write head

The individual goods are taken to the packing station in reusable containers. The containers are equipped with RFID tags. During filling, the product is assigned to the respective container. With each product gathered, an item in the order can be marked as completed. The tag makes it possible to track the path of the container through the intralogistics chain. RFID read heads at different stations on the conveyor lines detect the tags so that the track switches can be set appropriately and the path of the container can be steered onto the right track.

Technical Features:

- Connection with V1 connector (M12 x 1)

- Dual LED for function indicator

- IP67 rating

- For connection to the IDENTControl control interface

The Benefits

The RFID technology allows rational picking with the practically error-free identification of containers and products. The tags are considerably more rugged than the frequently used barcode labels and therefore have a longer service life. Picking is precisely controlled. Shipping volumes can be optimized and transport costs reduced. Data can be stored redundantly on the tags, enabling decentralized decisions to be made during the logistics process. In the event of faults in the process, this data can act as a backup and speed up the restoration of normal operations.

At a Glance

- RFID enables a higher degree of automation in order-related picking and packing

- Reliable identification of products; assignment errors virtually eliminated

- Automatic control of intralogistics speeds up processes

- Rugged technology, long service life

- Optimized shipping volumes reduce transport costs

- Information can be stored redundantly as a precaution

+44 161 6336431

+44 161 6336431